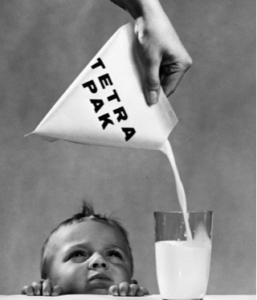

Tetra Pak

How Tetra Pak Changed Our Milk Habits

The Clinking Milk Bottles disappeared from your doorstep, replaced by Tetra Paks

Do you remember milk bottles that the milkman dropped at your doorstep? Well, I don’t because I grew up thinking that milk was always packaged in little sacks or cartons.

Milk bottles were the preferable mode of milk packaging. In some countries, milk was bought in bulk using containers and then utilised by pouring it into cans as needed.

This had multiple problems. The milk bottles had to be washed before returning, in some countries this was compulsory by law. What was the assurance that every bottle would be washed thoroughly?

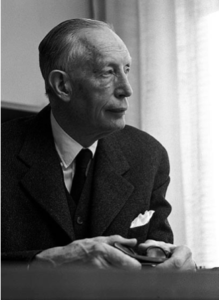

When Reuben Rausing sat to study his milk packaging market, he found several issues. The problem of hygiene, the problem of transportation, the losses by glass bottles being broken, the added space that they required and the problem of time limited utilisation.

Another type of packing was when milk was packaged in cartons. These cartons would leak and the way they were filled was wrong.

Milk was directly pored into them.

Have you noticed that when we pore milk, it froths. That’s what happened with those cartons. They had to be utilised fast too.

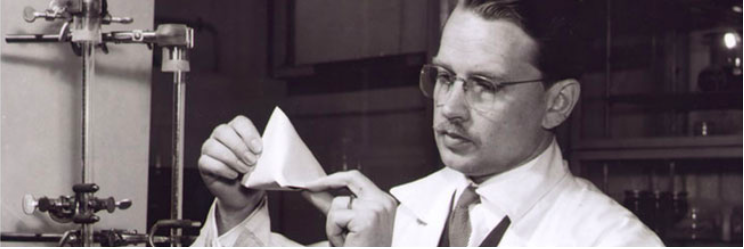

Erik Wallenberg came up with a solution for packaging. He said that a tetrahedron shape can be used to package milk. But he had no idea how to form, fill and seal the package or the material that had to be used.

Rausing liked the idea. He now had to solve all these problems and create revolutionary packaging. Mulling this in his mind, he went home for lunch one day. Help came from his wife.

Rausing’s wife was a genius. She gave him a one size fits all solution. Rausing tried this solution immediately after going back to work that afternoon.

He took a long rubber tube and filled it with milk. Then he used a heat sealing technique to seal small packages from the tube in a zig-zag manner. along the tube. This prevented the formation of froth. On tasting the milk, everyone agreed that it didn’t even smell burnt from the heat sealing!

Despite having found the solution in 1943, there was not enough technology to go ahead with mass production.

In the span of 10 years, the technology was developed.

Harry Järund made a machine using bicycle parts on the New Year’s eve of 1945. By September 1946, the actual machine was made. This machine helped seal the packs, hygienically.To gain recognition, Tetra Paks kept revising their material. Finally in September 1952, the first tetrahedron packs arrived.

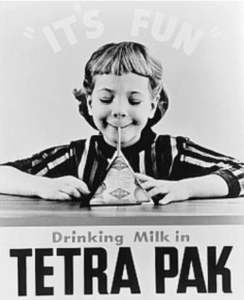

These packs solved many problems.

They could be stacked pretty much anywhere, even in the tiniest gaps in the refrigerator.

They could be resealed and consumed later.

They weren’t exposed to weather and were packed in a vacuum.

They could be transported across countries without refrigeration.

Hygienic pasteurised milk was available to everyone.

The packs were available in a variety of quantities.

From a 100ml pack to 1 litre.

The shape of the packs could fit perfectly in hexagonal crates. These crates were stacked on trucks and had special locks. This prevented them falling off.

The packs were lighter to carry and transport compared to the bottles. One truck would carry multiple packs.

All in all only 1 man could produce 5000 milk packs in one hour. That was a huge advancement.

Today, Tetra Pak is spread all over the world. They produce milk and dairy processing and packaging products.

The company also processes and packages other food products.

So next time you pop open the milk carton or the pack, think of Reuben Rausing and his 10 year fight to make the best packaging for you.

——–

This article is from the May Issue. To read the whole issue, please subscribe here and get your free online copy.

——–

Picture Curtesy to all images- Google Images